Please note this article contains sponsored links

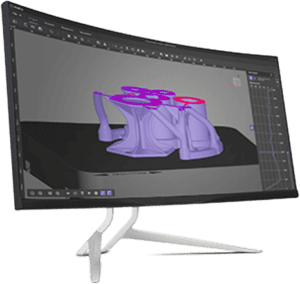

3D printing, also known as additive manufacturing, is a process of creating 3-dimensional objects by building up layers of material based on a digital model. It has applications in fields such as medicine, engineering, architecture, and product design. Popular materials used in 3D printing include plastics, metals, ceramics, and composites. 3D printers can range from small desktop models to large industrial systems.

Metal Additive Manufacturing (AM) is the process of creating 3D metal parts by building them up layer by layer, using metal powders, wires or sheets as feedstock. The process is also known as metal 3D printing. It is a rapidly growing field with a wide range of applications, including aerospace, medical implants, and custom parts for various industries. Metal AM offers the benefits of design freedom, low waste, and fast prototyping compared to traditional manufacturing methods like casting and machining. The most commonly used metal AM processes include Powder Bed Fusion (PBF), Directed Energy Deposition (DED), and Binder Jetting. pbf additive manufacturing (Powder Based Fusion) is a type of 3D printing technology that uses a laser or electron beam to melt and fuse metallic or polymer powders layer by layer to create a solid object.

Some notable successes of 3D printing so far in manufacturing include:

- Aerospace: Companies like GE and Airbus are using 3D printing to produce lighter and more efficient parts for aircrafts.

- Healthcare: 3D printing has been used for creating customized prosthetics, implants, and surgical tools.

- Automotive: Automotive manufacturers are using 3D printing to create prototypes and low-volume parts, such as engine parts and custom interiors.

- Consumer goods: Companies are using 3D printing to produce products like eyewear, jewelry, and phone cases.

- Construction: 3D printing has been used to create components for building structures, such as walls and roofs.

- Food: 3D printing is being explored as a way to produce customized food, such as pasta and chocolate.

These are just a few examples, and the technology is constantly evolving, with more applications being discovered as the technology develops.

The future of 3D printing is expected to see continued growth and innovation in several areas, including:

- Materials: Development of new, advanced materials that can be used for 3D printing, such as metal alloys, composites, and bio-based materials.

- Speed and efficiency: Improving the speed of 3D printing, as well as the quality and efficiency of the process, to increase productivity and reduce costs.

- Large-scale printing: Advancements in 3D printing technology that allow for the production of larger and more complex objects, such as entire buildings and vehicles.

- Mass customization: Increasing use of 3D printing to produce customized products at scale, such as personalized medical devices and consumer goods.

- Space exploration: 3D printing is expected to play a key role in enabling space exploration and colonization, by allowing for the production of parts and tools on demand.

- Industry 4.0: Integration of 3D printing into Industry 4.0, enabling smart and connected manufacturing, and leading to further advances in automation and digitization.

In summary, the future of 3D printing is expected to be characterized by continued growth, innovation, and the expansion of its applications across a wide range of industries. For more information on 3D printing, contact a 3d printing machine manufacturer